Dairypower has established a position as a staple of the modern slurry management industry. Since we introduced our unique, first-of-its-kind slurry management products to the Irish market in 1998, we have grown from strength to strength to a place where we have installed tens of thousands of bespoke slurry management systems across the entire globe. Our top-of-the-line slurry management systems offer tailor-made solutions which can be custom installed to suit the exact shape and size specifications that your farm or holding yard requires.

Our Eco-Friendly Systems

Dairypower has created the class-leading Smart Slurry Aeration System which is an environmentally friendly alternative to the traditional methods of tractor agitation systems. This aeration system avoids the production of harmful and toxic gases as well as increases the Nitrogen (and other nutrients) content available in the slurry. This increase can extend up to 70%, which is huge and can greatly impact the yield of your grass or silage.

Working in Harmony with the Environment

The well-known farming YouTuber, Tom Pemberton’s channel Tom Pemberton Farm Life focuses on reviewing and discussing farm life in the modern farming industry. His channel has almost half a million subscribers, indicating his popularity amongst agricultural experts and the farming community. He has grown to become one of the most respected farm educators and social media influencers in the agricultural industry, and in this article, we will take an in-depth look at his installation and review of our aeration system.

We installed this bespoke Smart Slurry Aeration System over one year ago on Tom’s farm, and have received several check-ins from Tom regarding how well it integrates with the day-to-day operation of Tom’s farming enterprise. See the video below for a visual diary of our system in full operation on Tom’s farm.

Video Installation Vlog

This video created by Tom Pemberton shows the entire process of this slurry aeration system installation and operation. As Tom explains, our system is all about “not having a crust form” on top of the slurry. Our aeration system moves the slurry all the time so there is no chance for any sediment to form. Tom says he was “fed up of” dealing with the lack of slurry management, the use of slurry bugs, crust formation and all of the additional health and safety precautions that comes along with slurry. Tom is very happy that the resulting slurry will be kept in a homogeneous state and avoid the need for any additional tasks in order to have a pumpable and spreadable slurry.

Tom’s system has been completely custom created and installed by our highly skilled team of experts. Our team has undertaken and completed this type of installation so many times that they can practically do it to the best standard in their sleep! This aeration system can also allow for a greater capacity availability of slurry storage compared to the old-school method where the slurry is allowed to separate and form a hard crust. Our system is so flexible on Tom’s farm that our team installed the slurry pipes in advance of the actual aeration pumps, as an electricity supply was not available at the time. This is an excellent indication of how adaptable our systems are. As Tom mentions in this review our system is a far more cost-effective solution than using slurry bugs which he indicates are much more expensive to utilise.

Installation Efficiency

This video reveals the full installation process from the absolute beginning to end. Watch Tom’s excellent video above to see in minute detail how each part of the installation is carried out.

To begin with, the aeration pipes are attached to the base of your tank or slurry storage with an industrial strength screw and bracket system, ensuring they are permanently fixed in place for years of optimal use. In the case of Tom’s tank, drills were needed to create holes for the screws to fix the pipes down. Tom even notes in this video how expertly our team of installers work when installing this equipment. There was additional time pressure on our team as the seasons were about to change coming into the autumn, where it is essential to have your slurry store set up and running before the winter hits your farm. This video displays the pipe fitting process and how effectively and neatly our team completed this task.

Tom notes that our system eliminates the need to hire any external contractors who would normally be required to pump water in and out of your traditional slurry store, in order to turn it into a homogenous and pumpable state before spreading on your fields. This one fact is a huge saving on your bank account!

Our team of experts will assist you at every stage of the installation process, including recommending the best locations for your pump and pipes for this aeration system. Tom notes that our team advised him to place the pump at a more suitable location than the one he originally had in mind.

Order of Installation

The pipes attached to the base of the slurry store are always fitted first and then the pipes leading to the aeration motor unit are fitted afterwards, of course in the neatest manner possible. Then it is time for the motor unit to be fitted and wired properly into the electrical system already present on the farm. Once this has been undertaken, then the motor unit can be connected to the pipes coming out of the slurry store.

You can also see the mechanism of this system in operation in this video. As soon as our system is turned on the slurry begins to mix and start its aeration journey to become homogenous all year round. It shows clearly how the system operates by using one pipe section at a time to pump bubbles into the slurry and then very efficiently move to the next pipe to perform the same function. “No more crust!” Tom exclaims to his delight. The farm will have better slurry in the long run in addition to saving costs in the long term. The video shows the absolute efficiency of this system, within two hours slurry the slurry crust had started to become liquid.

On-Farm Installations

One of the most significant benefits of this system is reduced running costs. Tom discovered that running costs will be approximately 50 pence per day. As times have changed more recently these are now running at approximately £1 per day, which is still very efficient considering the energy price hikes.

Our aeration system can operate between four to six times a day depending on your farm’s specific requirements. If you have a reduced night tariff for the electricity you can take advantage of this fact and run this system throughout the night. There is a recommendation to run the system at least once during the day, but the rest of the runs can be performed at night to keep the costs as low as possible.

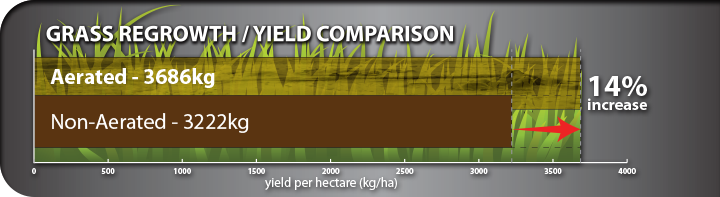

Our system is fantastic for promoting the growth of grass, as nitrogen is one of the most important nutrients to ensure that grass grows well. With an extra availability of 70% nitrogen, this should result in a 14% or so yield increase in your grass.

The system also reduces methane production by a minimum of 40%. Due to the fact that the slurry will be liquid all year round, the farmer can plan cropping and fertiliser use far in advance.

Tom is so happy with our product that he states purchasing and installing our system is one of the best investments he has made on his farm.

Reap the Benefits

Reap the full benefits of our custom install Smart Slurry Aeration System and find out more about our other cutting-edge industry-leading slurry management systems today. Visit our website at www.dairypower.com where you can also book a demonstration of our expert products.